I am the 3D printing Lead as well as an Aero-Structural team member on the University of Toronto Super Mileage Team (UTSM). Currently we are in the process of developing our 2nd ever Urban Concept Team aerobody.

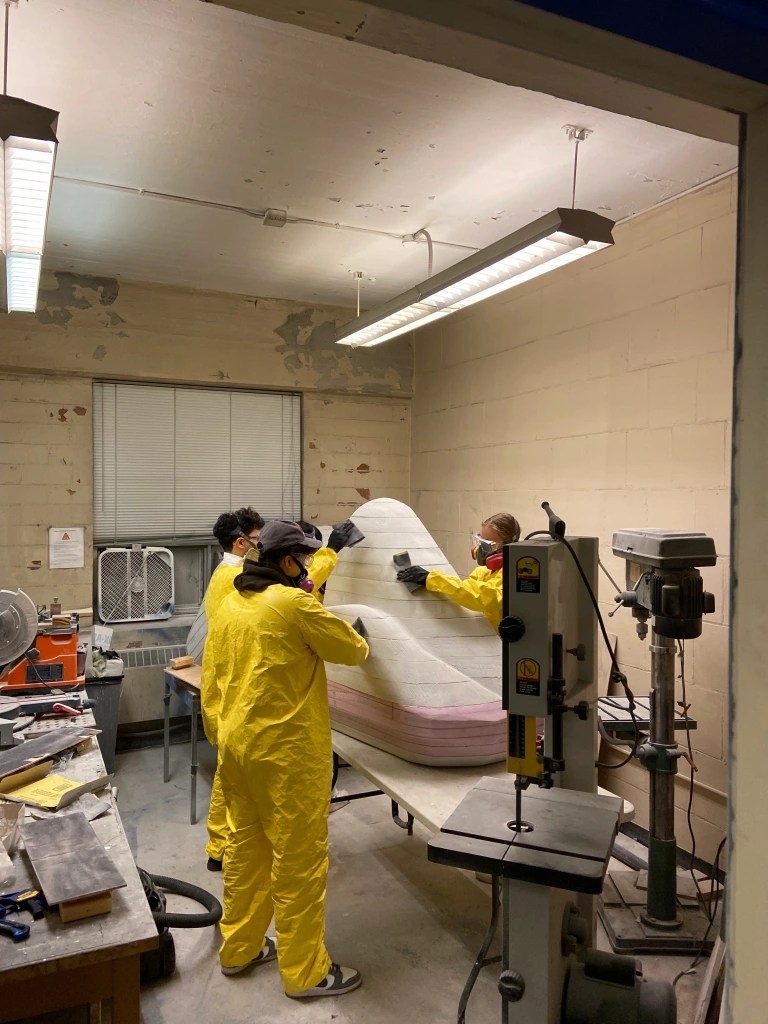

For our second iteration we have developed a more aerodynamic shape. First in Solidworks we create the car body then sliced this body into layers that would later be CNC’ed out of foam. I then assisting in the gluing of these layers together to create a rough body shape. Currently we are in the process of sanding down these layers of foam to create a smooth model.

Later on, we will layer fiberglass on top of this foam to create a hard-shell mold. Once we have this shell we can lay our 3 layers of carbon fiber with epoxy resin to create a strong aerodynamic body.

In my first year on the team I created carbon fiber wheel wells, floorboards and more for the car though a process called a layup. This involves pouring an epoxy over carbon fiber sheets and allowing them to cure while a vacuum sucks out excess resin. This creates an extremely resilient material and we will be using this same process to create our Aerobody.